简介:海洋上风和波浪会对海洋油气作业产生重大影响,不论风力、波浪、海流如何变化,钻井作业船和FPSO必须能够准确定位在某一点。

The winds and waves of the ocean can wreck havoc on offshore oil and gas operations. Whether a drillship is conducting drilling operations or an FPSO is serving as the development's production facility, offshore vessels must stay on position despite changes in the wind, waves and currents.

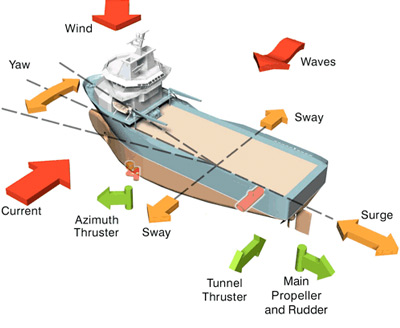

Forces Working on the Vessel

Source: Kongsberg

While offshore drilling in shallower waters allows a jackup to position itself on the sea floor above the location, drilling in deepwaters requires the rig, whether a semisub or a drillship, to float above the location. Taking into account that drilling equipment must sometimes span thousands of feet of water before even reaching the ocean floor, slight movements above the water's surface can have drastic effects on the drilling operations.

Additionally, some offshore developments require floating facilities. FPSOs and semisubmersible production facilities are positioned above the subsea development, housing production equipment and other machinery. Multiple risers connect the development below the water to the facilities above it. If the wind and waves knock the facilities off-track, the development would have to stop production and undergo extensive repairs.

Keeping floating equipment in position, whether performing drilling or production operations, is an important logistical aspect of the overall procedures. While drilling and production risers are somewhat flexible to provide for limited movements caused by the ocean currents, too much movement can break them and cause drilling or production to cease, as well as costly require repairs.

Like boats, floating facilities can be anchored to the ocean floor. According to the environment and the shape of the vessel, there are myriad ways to moor a vessel, which involves strategically anchoring the vessel by a number of lines to the ocean floor. Most recently, dynamic positioning has offered a more stable way to ensure that the vessel stays in position.

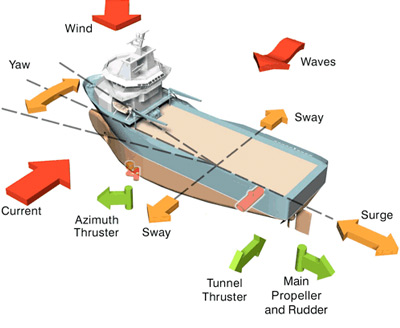

Dynamic Positioning

Source: Kongsberg

Dynamic positioning requires the vessel to have a number of thrusters, or powered propellers, throughout the vessel. These thrusters are located on the front and back, as well as both sides of the vessel, in order to maintain position from every direction.

A computerized system automatically employs the thrusters when it is necessary. Information about the position of the vessel is communicated from special sensors on the ocean floor. Additionally, satellite communications and weather and wind information is transmitted to the computer system, further helping it control the movements of the vessel. Using the information provided to it, the computer automatically engages the thrusters to overcome any changes in the location of the vessel.

Sometimes mooring and dynamic positioning are used together to keep the vessel on position. Additionally, with a dynamic positioning system, these vessels many times can stop operations and move out of the way of threatening storms, such as hurricanes and cyclones, further strengthening the safety of the offshore development.

杨宝剑 是全球石油网的高级技术编辑,在石油技术资讯行业有八年的学识和经验。他源源不断地提供石油行业全球最新的技术创新、研发成果、现场应用情况等信息。如果你对“新技术新产品”的内容有任何问题或建议,请联系杨宝剑编辑 +86 10-58236512 Email:allenyo@zhenweiexpo.com 欢迎您提供手中的最新技术文章!