简介:由巴西石油和FMC联合开发海底分离系统,将在巴西Marlim 海上油田部署。该系统主要目的是克服采油设施的瓶颈,通过分离不必要的水分,来提高海底采油的产量。系统包括海底分离、泵送和水回注。设备安装水深可达900米,能够处理含气、油、水和沙的油流,其中包括重油。具体是首先分理出气体,然后采用新型油水分离设备将水和重质油分离开来,再除砂,然后将气体回注重油中,以提升油流的举升能力,同时分离水回注地层,进一步的促进产量提升。

巴西油田位置图

FMC Technologies has been awarded a USD 90 million-contract by Petrobras to supply a subsea-separation system for the mature, deepwater Marlim field in the Campos basin, offshore Brazil. The contract marks the first deepwater deployment of subsea-separation technologies in a mature field and the first separation of heavy oil and water in a subsea environment.

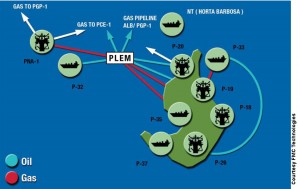

In operation since 1991, Marlim is Petrobras’ largest field in the Campos basin and is located in water depths ranging from 2,100 to 8,500 ft (650 to 2 600 m). With 129 wells and 8 floating production units (FPUs) devoted to oil and gas production, the field was once considered the world’s largest subsea development. Nearly 20 years of operation has brought about increasing production of water?which limits the oil-handling capacity of the surface facilities?and sand?which could potentially damage the system’s internals.

The main purpose of the subsea-separation system is to debottleneck the FPU and increase production by removing unwanted water from the production stream at the seabed. The scope of supply consists of a subsea-separation, pumping, and water-reinjection system, developed jointly by Petrobras and FMC.

The system will be installed at a depth of 2,950 ft (900 m) and will receive the production stream?which contains a mixture of oil, gas, water, and sand. It will first separate the gas from the liquids and then the heavy oil will be separated from the water using a novel pipe-separation design that was licensed and developed by FMC in cooperation with StatoilHydro.

The system also integrates FMC’s proprietary water-treatment and sand-handling technologies as part of the subsea-separation system. The separated gas will be added back to the oil stream to aid its lifting to the FPU, while the separated water will be pumped back into the reservoir to further increase production. This also marks the first time this system has been used to reinject water to increase reservoir pressure and boost production, according to FMC.

Marlim is the fifth project awarded to FMC that will utilize subsea-separation technologies. Other projects include StatoilHydro’s Tordis field, Shell’s Perdido and BC-10 developments, and Total’s Pazflor field.

The equipment will be jointly engineered among FMC’s operations in Brazil, Norway, and The Netherlands. Final manufacturing and integration activities will be performed at the company’s Rio de Janeiro facility, with deliveries projected to begin in 2011.

For more information, please visit

FMC Technologies’ subsea systems web page.

杨宝剑 是振威(全球)石油网的高级技术编辑,在石油技术资讯行业有八年的学识和经验。他源源不断地提供石油行业全球最新的技术创新、研发成果、现场应用情况等信息。如果你对“新技术新产品”的内容有任何问题或建议,请联系杨宝剑编辑 +86 10-58236512 Email:allenyo@zhenweiexpo.com 欢迎您提供手中的最新技术文章!